Inclines

Inclines

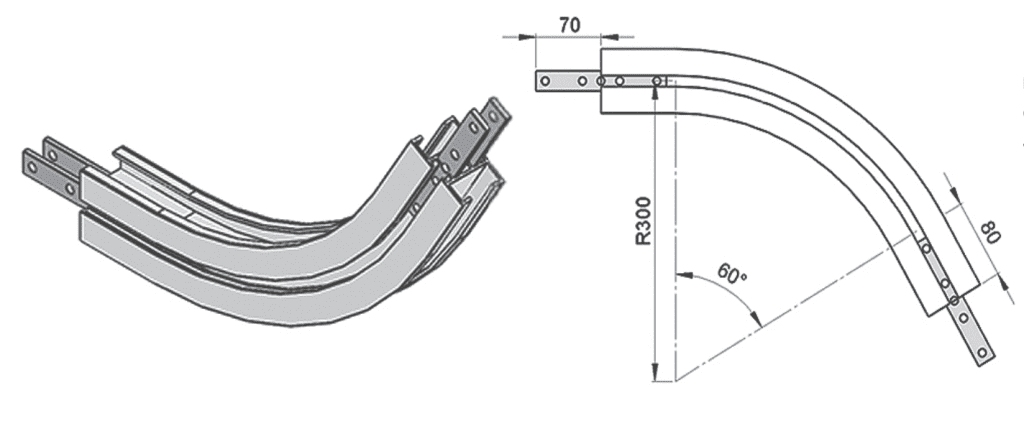

Inclines and declines are achieved through the use of vertical bends. A vertical bend provides vertical change of the conveyors moving direction. It can be used either as a convex or concave bend. Vertical bends increase the chain tension and cause higher stress on the slide rail. Avoid using more than four 90° vertical bends in one conveyor.

Vertical bends are available in 5 degree increments up to 90 degrees.

WHY Flexmove?

Flexmove offers one of the best systems on the market popular with many bluechip companies throughout the world. And you can see why…

Unrivalled Support

We offer the best support in the industry, from build to installation and ongoing support we are here.

Expandable

Our systems are fully expandable, if you need to make adjustments parts can be added to create your perfect system.

10 Year Warranty

A huge 10 year warranty is given on all of our conveyor systems and parts, giving you peace of mind.

Free Design Service

Need help designing your system? We have an in-house design team that will work with you to design your system.

Easy Self Install

All Flexmove conveyor systems are easily constructed enabling you to take delivery and build yourself on-site.

Cost Effective Solution

Flexmove is the most cost effective solution on the market and parts and modules can be replaced when needed.

Our wedge conveyors are used to take products from production floor level to a higher level or vice versa. Products are wedged between opposing conveyors lined vertically or horizontally and are moved swiftly but securely. Wedge Conveyors are easy to construct, lightweight and have compact footprints. Its rapid transfer rate makes it ideal for use in continuous, high capacity operations such as packaging lines. Built with Aluminum and stainless steel, it meets the stringent hygiene standard required for medical and cosmetic packaging. Wedge Conveyors can be configured differently for a variety of uses, such as a transition between different travel orientations, de-pucking operations, inverted rinse operations and even for creating a passage way on the production floor. Wedge Conveyors are not suitable for wet products, heavy products or products that cannot withstand side pressure.

Create your own custom conveyor with Dorner s industry leading CAD/Configurator software. With DTools, designing a conveyor that meets your specific application is quick and easy. Submit a request for complete custom systems or replacement parts for your existing conveyor, and get a free quote and CAD design fast!

Need Help?

Please get in touch to discuss products, system setups and applications for your business needs.

01772 690656

Have A Question?

Can these drives be used on any system?

Your description goes here. Edit or remove this text inline or in the description settings

Is there a warranty on drives?

Your description goes here. Edit or remove this text inline or in the description settings

What is the maximum torque on your drives?

Your description goes here. Edit or remove this text inline or in the description settings