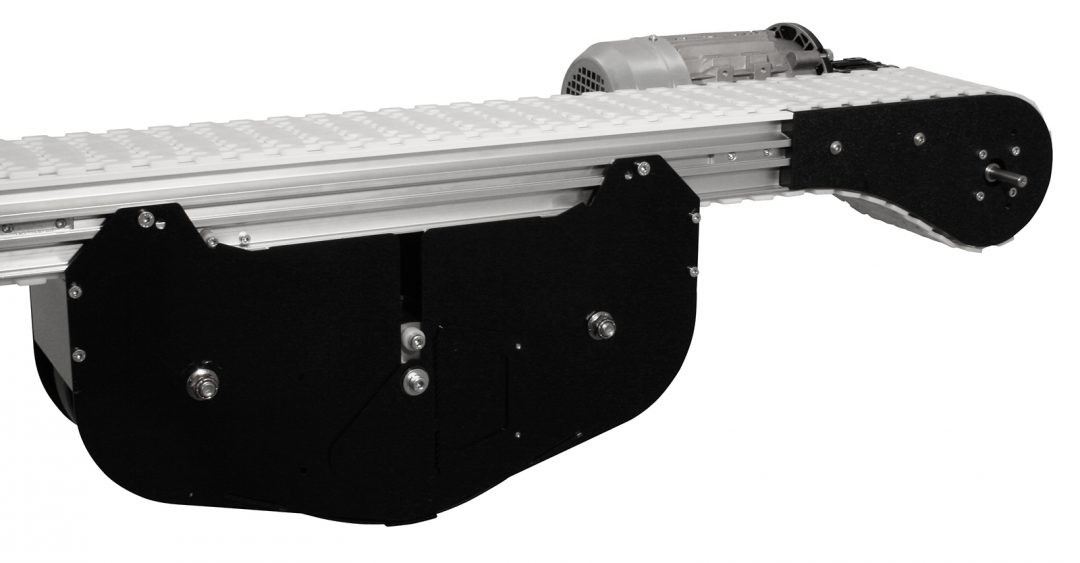

Conveyor Drives & Idlers

Reliable Drive Systems

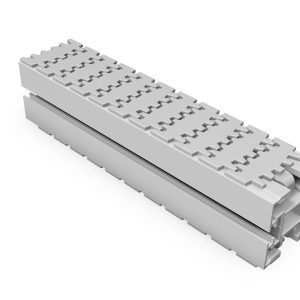

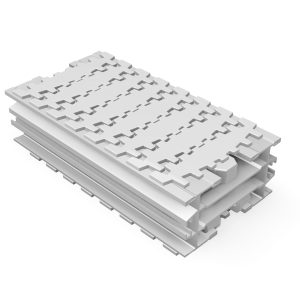

Introducing FlexMove conveyor drives, the innovative solution for seamless and efficient material handling. At FlexMove, we specialize in slat conveyors and modular plastic chain conveyors, connecting possibilities for businesses across various industries.

Our conveyor drives are engineered to deliver exceptional performance, reliability, and durability. With a focus on quality and precision, our drives offer maximum torque, ensuring smooth operation and enhanced productivity. And to provide our customers with peace of mind, we offer a comprehensive warranty on all our drives. Discover the power of FlexMove conveyor drives and elevate your material handling system to new heights.

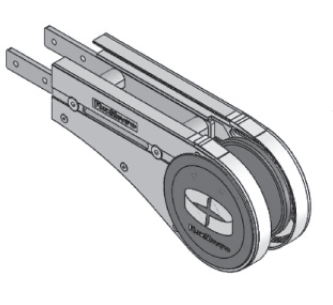

The function of the idler end is to change the direction of the moving chain. Available in both standard idler end unit (180º) and idler bend unit (90º). It comes with 2pc connecting strips at the connection end.

WHY Flexmove?

Flexmove offers one of the best systems on the market popular with many bluechip companies throughout the world. And you can see why…

Unrivalled Support

We offer the best support in the industry, from build to installation and ongoing support we are here.

Expandable

Our systems are fully expandable, if you need to make adjustments parts can be added to create your perfect system.

10 Year Warranty

A huge 10 year warranty is given on all of our conveyor systems and parts, giving you peace of mind.

Free Design Service

Need help designing your system? We have an in-house design team that will work with you to design your system.

Easy Self Install

All Flexmove conveyor systems are easily constructed enabling you to take delivery and build yourself on-site.

Cost Effective Solution

Flexmove is the most cost effective solution on the market and parts and modules can be replaced when needed.

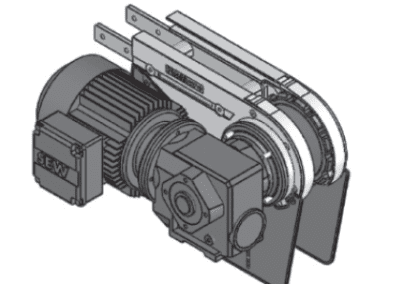

An intermediate drive is best utilized when space restriction prohibits the placement of the end drive unit. It required two idler end units at each end. The gear motor can be coupled directly or suspended underneath the drive unit at both right and left orientation. Adjustable torque limiter can be added to protect the conveyor system. The traction force is lower than other end drive units due to less engagement between drive sprocket and chain.

Catenary Drives are designed to accommodate top-running chains and are commonly used in application of single loop or alpine conveyor system. Additional idler end unit is not required. Only suspended version is available.

A combined drive and idler consist of one end drive and one idler end unit mounted in a single assembly with a transfer bridge for smooth transfer of products. It has a smaller footprint compared to side transfer design. Available in both direct and suspended drive versions, the gear motor can be coupled at both left and right orientation. Adjustable torque limiter can be added to protect the conveyor system.

Wheel drives are used for applications using a single loop or alpine conveyor systems without a return chain.Both direct and suspended drive versions are available with the Gearmotor mounted underneath. The traction force is lower than other end drive units as the gear wheel engages the side of the chain.

The function of the idler end is to change the direction of the moving chain. Available in both standard idler end unit (180º) and idler bend unit (90º). It comes with 2pc connecting strips at the connection end.

Idler End Unit (standard 180º)

The moving chain is transferred 180° from the bottom of the conveyor beam to the top through a flange guide with minimal friction.

Idler Bend Unit (90º)

The idler bend unit converts and changes the chain direction in 90º perpendicular to incoming chain direction.

Create your own custom conveyor with Dorner s industry leading CAD/Configurator software. With DTools, designing a conveyor that meets your specific application is quick and easy. Submit a request for complete custom systems or replacement parts for your existing conveyor, and get a free quote and CAD design fast!

Need Help?

Please get in touch to discuss products, system setups and applications for your business needs.

01772 690656

Have A Question?

Can these drives be used on any system?

Your description goes here. Edit or remove this text inline or in the description settings

Is there a warranty on drives?

Your description goes here. Edit or remove this text inline or in the description settings

What is the maximum torque on your drives?

Your description goes here. Edit or remove this text inline or in the description settings